BIO-UV Gamme IBP+

ACS Food Industry Certified UV Reactor - BIO-UV®

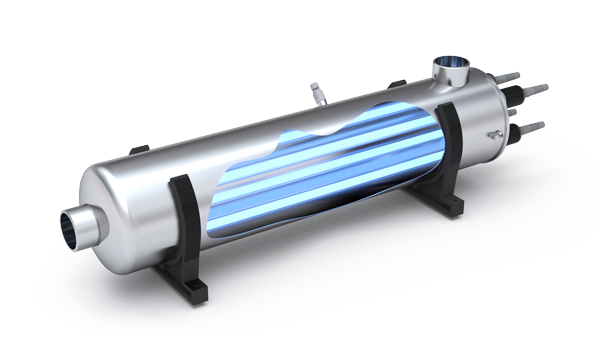

THE IBP + RANGE (CERTIFIED ACS FOOD INDUSTRY)

Industrial water treatment

BIO-UV Group water purification devices are suitable for the treatment of industrial process water. They provide operators with the possibility of securing their production and guaranteeing satisfactory water quality.

The main applications of BIO-UV water purification devices are:

- Disinfection of industrial process water

- Disinfection of washing and rinsing water

- Protection downstream of membrane treatment systems (reverse osmosis, ultrafiltration, etc.)

- Maintenance of stored water quality: raw water, treated water, ultra-pure water

- Dechlorination: reduction of the free chlorine level

- Dechloramination: reduction of the combined chlorine level

Legionella prevention

Legionella are present everywhere in the environment. They particularly affect air-cooling towers and domestic hot water circuits, finding favorable conditions for their development. The production of aerosols contaminated by Legionella is a risk factor linked to public health.

BIO-UV Group has developed a concept of preventive treatment against Legionella, which aims to erect a real bacteriological barrier each time a risk factor is identified:

- UV treatment of inflow water

- UV treatment of circulating water

- UV treatment coupled with a preventive treatment of biofilms

Household disinfection

- The BIO-UV Group reactors of the IBP HO + range allow:

- Disinfection of raw water from local resources (wells, boreholes, catchments, etc.)

- Securing network water, after dechlorination on activated carbon in particular

- Securing recycled rainwater for sanitary use only

BIO-UV Group reactors guarantee compliance with the bacteriological quality limits of water (according to the decree of 25/12/2003) and comply with the Directive of the Ministry of Health relating to UV treatment. Prior filtration may be necessary.

Advantages

- Excellent performance in disinfection through extensive optimization of UV emissions and hydraulic flow

- Compact reactors for easy installation

- Use of single-ended lamps, patented sealing system and vertical design for easy maintenance

- UV sensor and monitor, optional, offering an alarm by diodes and dry contacts for reporting information

- Connection customization possible: DN flanges, clamp, SMS

- Combination in advanced oxidation with catalysts

- Optimized lamp life: 13,000 hours depending on number of ignitions

The operation of the reactor is continuously monitored:

- The electronic ballast ensures proper operation of the lamps and associated alarms

- A selective UV sensor monitors the end of life of the lamps

- Quartz sheath fouling control

- Water quality monitoring and associated alarms

- The information given by the sensor can be recorded to ensure the traceability of the operation of the reactor.

Benefits

- Simple treatment to implement, which does not modify the physico-chemical characteristics of the water: no modification of taste, smell...

- No creation of disinfection by-products harmful to human health

- No risk of underdose or overdose

- No tracking and chemical handling constraints

- Possible combination with other treatment processes (filtration, softening, etc.)

- Advanced Oxidation Treatment with the presence of catalysts

- Efficacy against legionella proven by independent and approved laboratories

- Effectiveness for the preventive treatment of DHW towers and networks (Domestic Hot Water) through targeted and strategic use of UV rays according to each installation

- Guarantee of continuous disinfection in possible combination with other water treatment systems (anti-scaling, anti-corrosion, etc.)

- Simple and economical treatment.