Ultrafiltration solution for scrap metal shredder

Treatment of fumes, dust, VOCs, dioxins, PCBs emitted during the shredding of scrap metal or ELVs - KELLER Lufttechnik GmbH

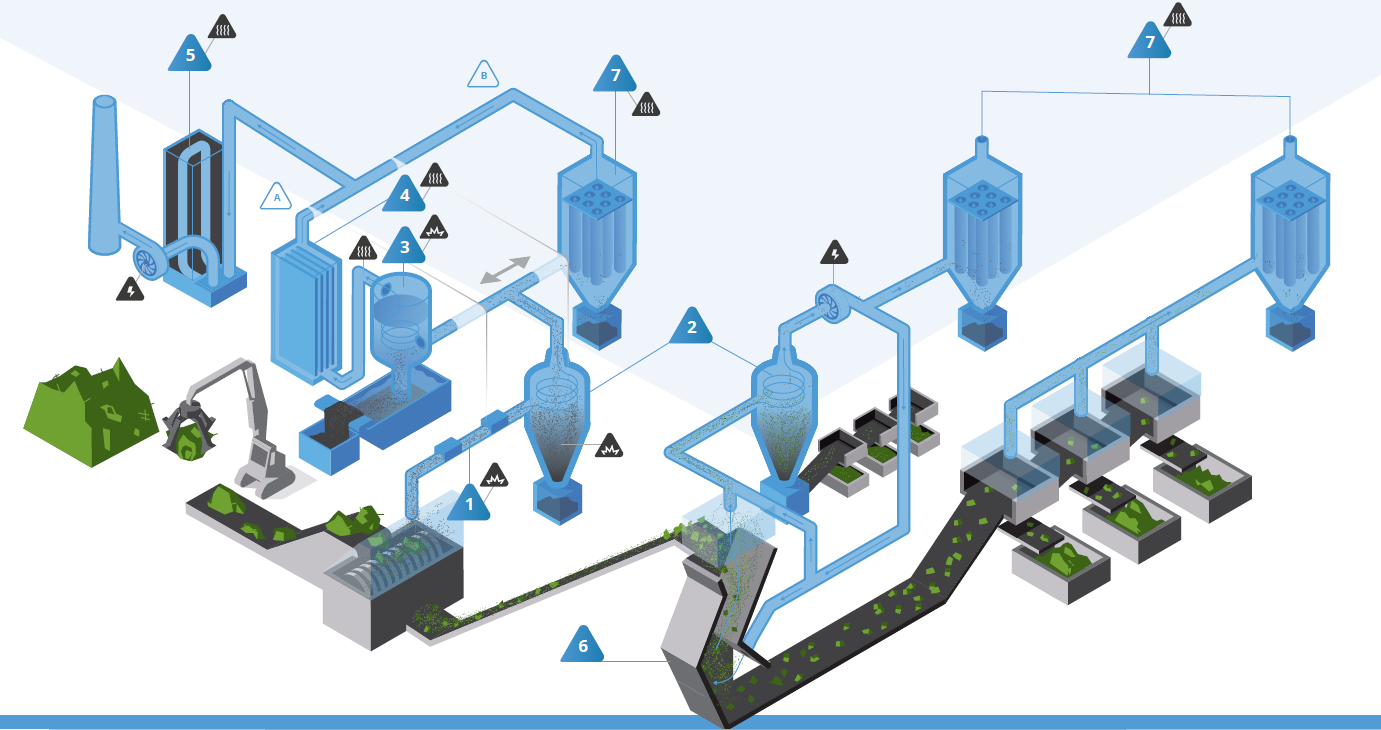

The various dust pollution points of the mills are sucked into a first dry or wet filtration system. VOCs are only filtered well when the air flow is free of dust. We therefore set up an ultrafiltration system to filter all the solid particles and then be able to treat only the gaseous effluents in an activated carbon box. For any dust collection installation, the requirements for energy consumption, explosion and emissions are taken into account.

BLAST

The installations are designed to allow the restart of your production process as soon as possible in the event of an explosion. Our designs systematically take into account the protection of personnel and the environment against the effects of an explosion.

ISSUE

Thanks to Keller's wet venturi separator, low dust emission values can be achieved. With dry dedusters from Keller, even lower emission values are achieved. For the suction and ventilation of aeraulic cascades and cleaning and sorting lines, dry process dust collectors can be used.

VOCs (volatile organic compounds) and odors are neutralized by the use of an activated carbon filter. When using Keller ultrafiltration units, the service life of the activated carbon is greatly increased.

ENERGY

Energy consumption is limited thanks to calculations and an optimal design of our cyclones, our pipes and our filtration systems.